It almost seems counterintuitive to imagine touchscreen computers in an industrial workplace. Grime covered gloves or hands touching a computer screen seems like it would lead to more problems than it solves. But then again, is it any better that the same gloves or hands are touching a mouse and keyboard? The shocking reality is […]

Tag: Industrial Computers

Industrial PCs For Desert Use

There’s one environment that is seemingly designed to destroy computers from the inside out. Scorching heat that prevents CPUs from cooling down, kicked up sand that threatens to short circuit motherboards, and a cascading environment that can change in the blink of an eye. If you haven’t guessed it by now, I’m referring to the […]

Industrial Computers for Car Wash Tunnel Systems

When it comes to car wash tunnel control systems, most car washes are stuck in the past. Bulky, ancient control systems dominate the market, requiring an extensive and specific knowledge to operate and maintain. Computer power has risen exponentially over the past decade, and these archaic systems not only lag behind in usability, but in […]

Tangent Covers All Bases in PC Needs

The average company doesn’t typically replace their computers all at once in a mass hardware refresh. Over years of use, certain models are phased out for newer ones or replaced because of age. And as business processes change and newer software suites require specific system configurations, a wide assortment of computer systems tend to be […]

A Tablet to Fit Industrial Tasks

The job requirements for an industrial refinery’s quality control inspector are understandably hefty. They are required to monitor mechanical works in progress and evaluate completed work to ensure compliance with applicable codes and safety standards. In their work day, they are often on-site reviewing and comparing mechanical drawings for code compliance and for requirements on […]

Dressing the Part for Modern Industry

Dressing the Part for Modern Industry Interior design legend, Elise de Wolfe, once said that dressing well is largely a question of detail and accessories. As much as this philosophy applies to fashion and design, it can also be said that a great computer system is largely contingent on the details built into it, versatility […]

Industrial Computers – Conducting Business in Extreme Conditions

Industrial Computers – Conducting Business in Extreme Conditions It’s no surprise that extreme weather can have a significant impact on industrial operations, which often times take place while on the move or exposed to the elements. For military personnel working in Afghanistan, summers are blistering hot and winters can be bitterly cold, and a 2007 […]

Fanless Computers: Still Running Cool!

Fanless Computers: Still running cool! Making a computer with a single fan is good engineering, making them fanless is an art. TANGENT offers fanless computers which are reliable and robust to meet your demanding requirements of ruggedness and performance. What are major problems with the fans that require us to build fanless computers? Noise: […]

Industrial Computers: Solutions for Modern Factories and Workplaces

Industrial Computers Every part of our lives has started revolving around the need for computers and automation. The shift from an analogue way of life to an automated way of life has been quite sudden. Computing has become an integral part of industries, but the needs for the right hardware is most certainly different. It […]

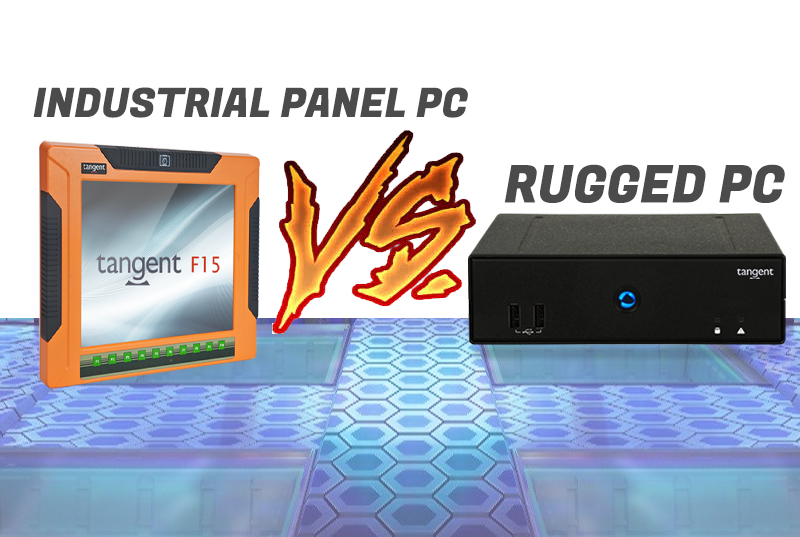

Industrial VS Rugged Mini PCs

Industrial vs Rugged Mini PCs: What’s the difference? Tangent Industrial PCs can be found in air, water and land vehicles such as trains, tanks, submarines, boats and emergency vehicles. Tangent Rugged Mini PCs can also be found in the above-mentioned vehicles but are designed to go one step further in ensuring consistent performance and reliability […]