5 Ways Medical Computers Excel over Consumer PCs There’s a good reason why the healthcare field is one of the most heavily regulated industries with the most oversight. When it comes to patient care, painstaking efforts are necessary to protect everyone at a medical facility including staff and visitors. Everything including medical equipment needs […]

Month: March 2019

No Dust Bunnies This Easter…

No Dust Bunnies This Easter… Finding dust build up inside a fan-cooled computer is like finding traffic in LA. It’s always there no matter how much you try to avoid it. Thousands of hours of fan-driven air movement and electrostatic charges make the internals of a PC or laptop a prime dust magnet. From […]

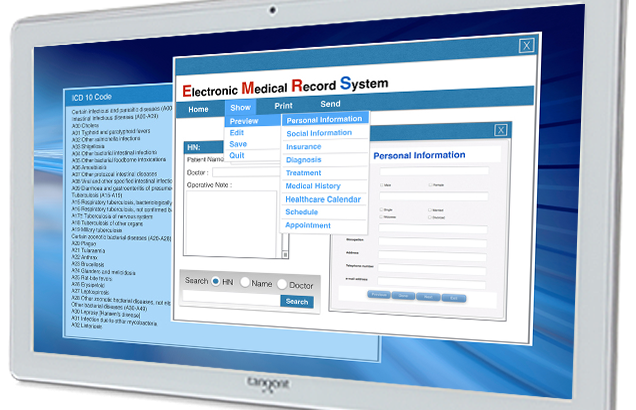

The Difference Between a Panel PC and a Tablet

The Difference Between a Panel PC and a Tablet An industrial grade touchscreen panel PC may have many of the same features as a tablet, but its purpose is to provide an incredibly durable, impenetrable, fast, and powerful computer system that will last for many years. Tangent offers four lines of industrial panel PCs […]

3 Essential Features of Medical Computers

3 Essential Features of Medical Computers “Medical grade computer” isn’t a label you can slap on anything off the shelf. Understandably, there are stringent regulations around what can be considered a safe computer component for use around patients in healthcare environments or in highly sanitary conditions. Medical computers are designed to be installed in […]