Dressing the Part for Modern Industry Interior design legend, Elise de Wolfe, once said that dressing well is largely a question of detail and accessories. As much as this philosophy applies to fashion and design, it can also be said that a great computer system is largely contingent on the details built into it, versatility […]

Month: July 2018

Invisible Threats

Invisible Threats Hospital equipment often is advertised as being antimicrobial, but how is it possible for a LCD monitor or tablet computer to ward off pathogens in a medical setting without being wiped down with disinfectants all the time? It seems odd for a collection of plastics and wires to promote any sort of health […]

Fanless Computers: Progress in Silence and Longevity

Fanless Computers: Progress in Silence and Longevity Prior to the mid 70s, computers were typically very large industrial or commercial machines, often housed in a dedicated room with an equally sized cooling system. Noise was not a notable issue for users because the computers were isolated industrial devices, viewed much like any other heavy duty […]

Shaping up Shipping and Receiving : One Panel PC at a Time

Shaping up Shipping and Receiving : One Panel PC at a Time Staying on top of technological advancements for shipping and receiving operations is important for a good number of reasons, but the most pivotal are business process improvement for increased revenue, and ensuring safety in the workplace. E-commerce is greatly driving the need for […]

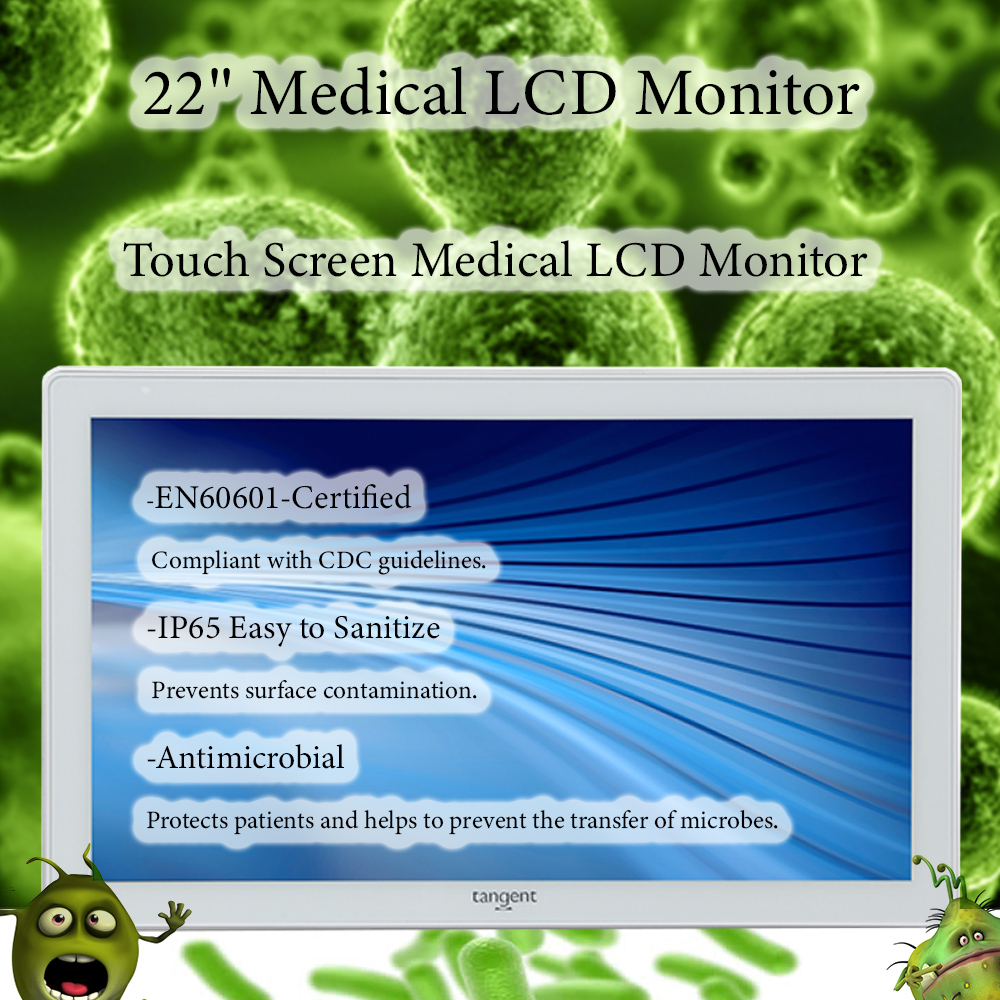

Medical LCD Monitors

Medical LCD Monitors The CDC largely cites government agency regulations and the Spaulding Classification Scheme when determining recommendations for maintaining a safe medical environment regarding the cleanliness of equipment involved with or in the vicinity of treatment. In the early 90’s, OSHA (the Occupational Health and Safety Administration) enacted a standard called “Occupational Exposure to […]

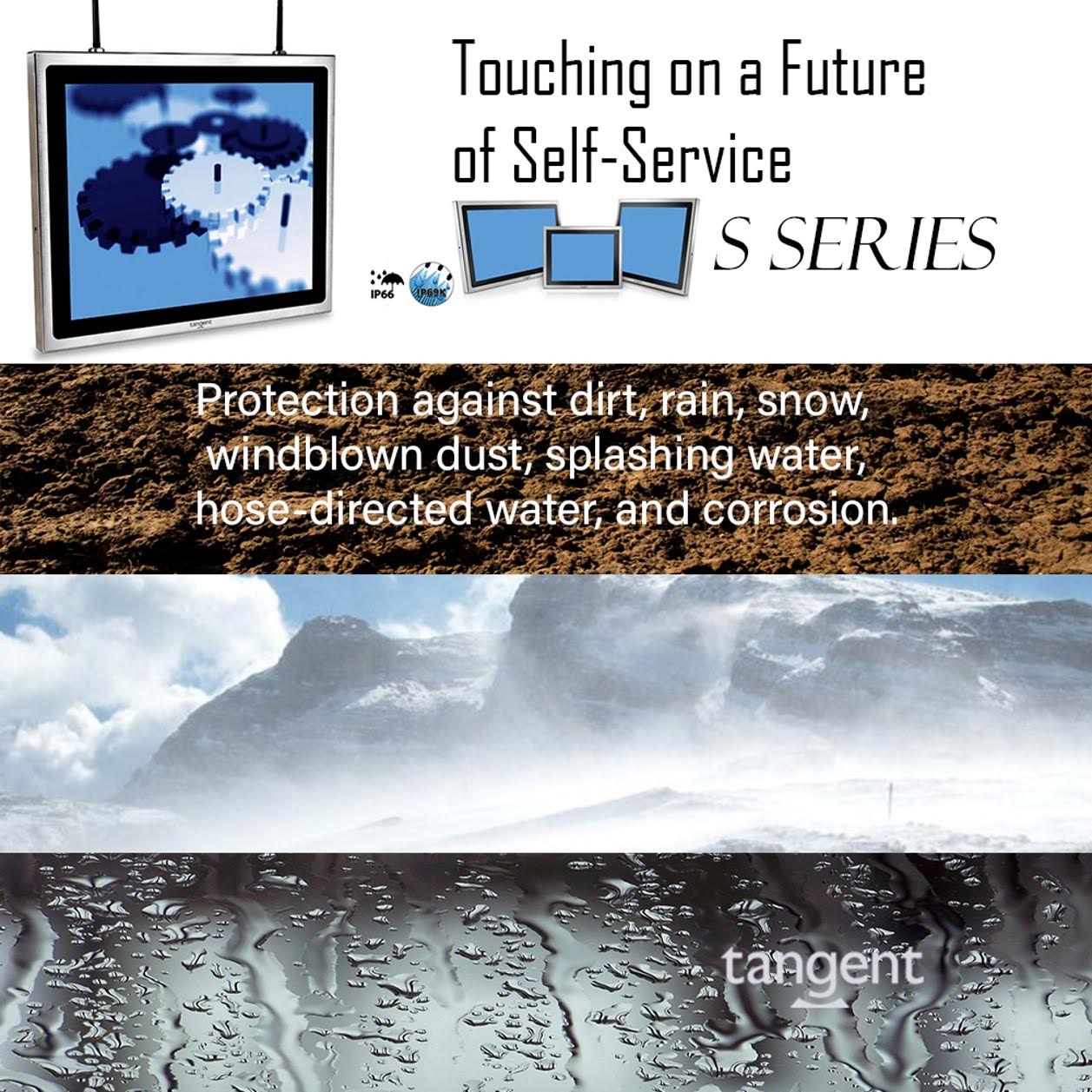

Touchscreen Computers – Touching on a Future of Self-Service

Touchscreen Computers – Touching on a Future of Self-Service Over the last couple decades, self service technologies have revolutionized how people conduct business, travel and even receive healthcare services.These technologies have vastly improved efficiency through increased control over service delivery, convenience, reduction in wait time, reduction in operating costs, and flexibility in use. At many […]

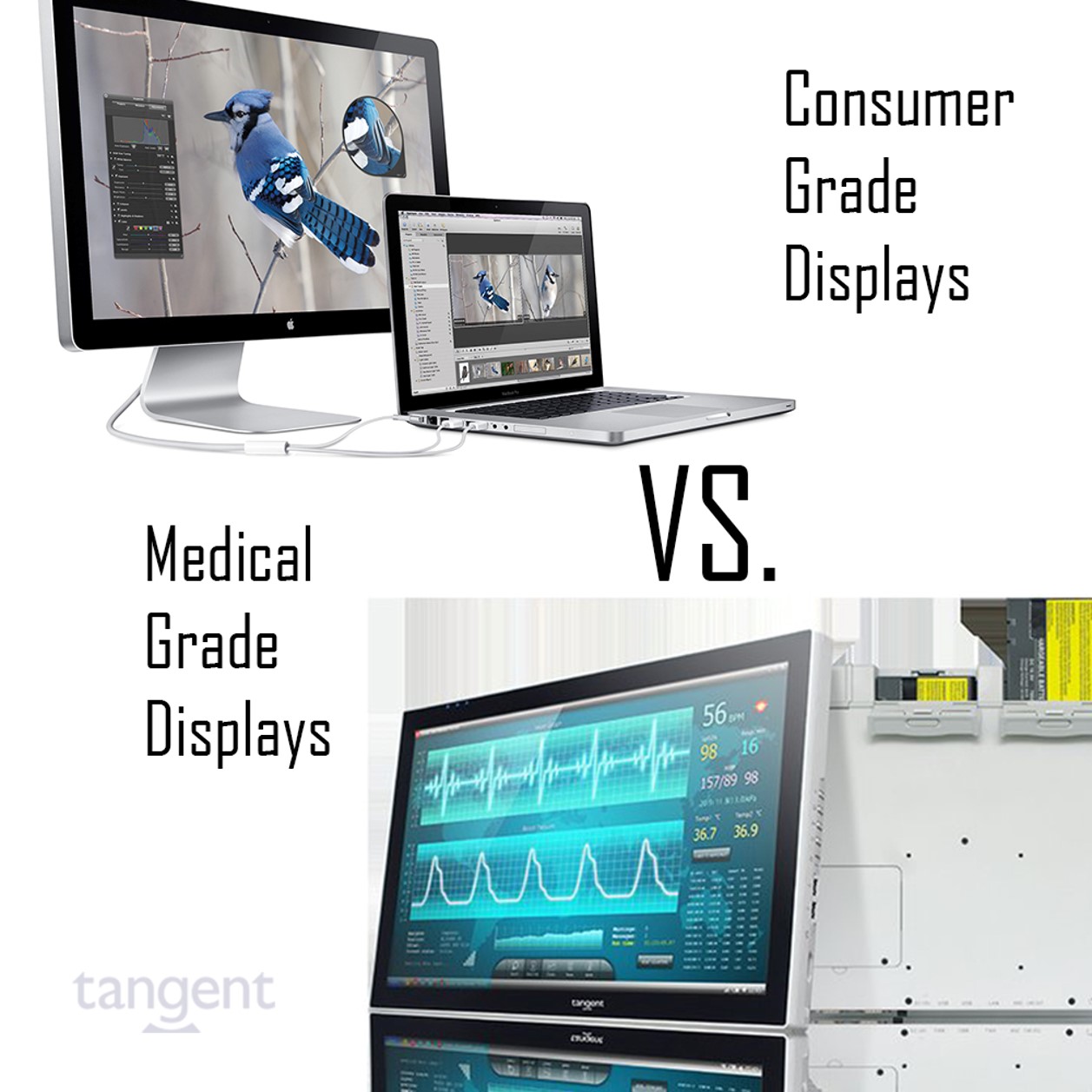

Consumer Grade vs. Medical Grade Displays

The importance of selecting Medical Grade Displays for your Healthcare Application Although there is a wide availability of display solutions to meet the demands of hospital and diagnostic requirements, not every solution can provide the quality, consistency, or longevity necessary for successful operation and patient satisfaction. Hospital staff often do a double take when they […]