The average company doesn’t typically replace their computers all at once in a mass hardware refresh. Over years of use, certain models are phased out for newer ones or replaced because of age. And as business processes change and newer software suites require specific system configurations, a wide assortment of computer systems tend to be […]

Maintain a Healthy Workforce with Tangent

Promoting clean and sanitary work areas isn’t just incredibly impactful in medical settings. Illness costs US employers $530 billion per year in lost productivity, per a 2018 report from the Integrated Benefits Institute (IBI). Thomas Parry, IBI’s President says that the cost of poor health to employers is greater than the combined revenues of Apple, […]

Sticking With What’s Important

The big buzz in tech news this week is an audacious and eyebrow raising product release from Apple. That’s not surprising coming from a company known for their high dollar gadgets and phones, but they really seem to have outdone themselves this time. For just $999, the world can own a new Apple monitor stand. […]

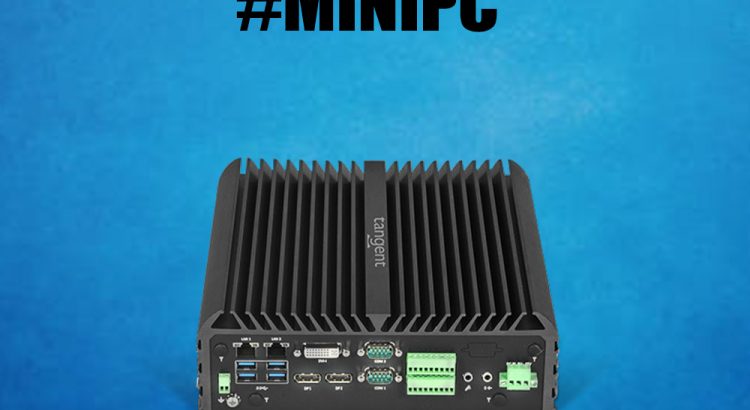

Ports Ports Ports!

The Tangent E2 industrial mini PC is a literal lightweight at 4.6lbs and a petite 7.28″ x 7.75″ x 2.26″ frame, so it is shocking that there are over 21 input/output ports packed into it. Not only are they plentify, some are brightly colored for ease of use in the dark. Why in the world […]

A Tablet to Fit Industrial Tasks

The job requirements for an industrial refinery’s quality control inspector are understandably hefty. They are required to monitor mechanical works in progress and evaluate completed work to ensure compliance with applicable codes and safety standards. In their work day, they are often on-site reviewing and comparing mechanical drawings for code compliance and for requirements on […]

The Importance of Security and Medical Grade Hardware

On May 14th, Simon Pope, a director at the Microsoft Security Response Center, wrote a blog post urging users of older Windows operating systems to install security patches on their computers and take steps to secure themselves from a known vulnerability that could be exploited and result in worm infections and/or cyber attacks. The remote […]

Every Minute Counts with Cardiac Arrest

When cardiac incidents occur in a hospital, every minute that passes can be a factor in whether the patient survives or not. According to Heart.org, in 2016, only about 25 percent of U.S. patients survived when their hearts stopped in a hospital. With how busy medical staff are and the amount of alerts going off […]

EHR and Patient Care Ready

Epic Systems is world-renowned for their electronic health records software, but their portfolio has expanded to do much more than just maintain records in the patient care space. They understandably have specific system requirements for successful use of all their powerful features. The recommended screen resolution on a system running Epic is 1920×1080 with at […]

Mobile Phone vs Medical Tablet: What’s Best in Healthcare?

Technology you encounter at hospitals can be a tad confusing or funny at times. You see million dollar state-of-the-art scanners and treatment machines, but then you also see a doctor walk by with a 90s style pager clipped to their pocket. The reason for this is that they both suit their purpose best. The […]

Doing A Whole Lot With Very Little (Computers)

To most hourly employees, the work time clock is an annoying, but necessary evil. To payroll departments, it’s the most essential tool in the galaxy. And to IT departments, it’s something that needs to be available in lots of places around the company floor but also, out of the way. Most modern time clock stations […]