Invisible Threats

Hospital equipment often is advertised as being antimicrobial, but how is it possible for a LCD monitor or tablet computer to ward off pathogens in a medical setting without being wiped down with disinfectants all the time? It seems odd for a collection of plastics and wires to promote any sort of health benefits, but medical advancements and information technology have long gone hand in hand. Antimicrobial additives can now be blended into plastic surfaces during the manufacturing process to provide lasting protection from microbes, harmful bacteria, mold, fungi and viruses. This minimizes the risk of the spread of infection, staining, smells, and material degradation. When you take into account that hospital associated infections have caused more than 100,000 deaths in the United States, it’s no wonder that great efforts are made to sterilize every surface possible.

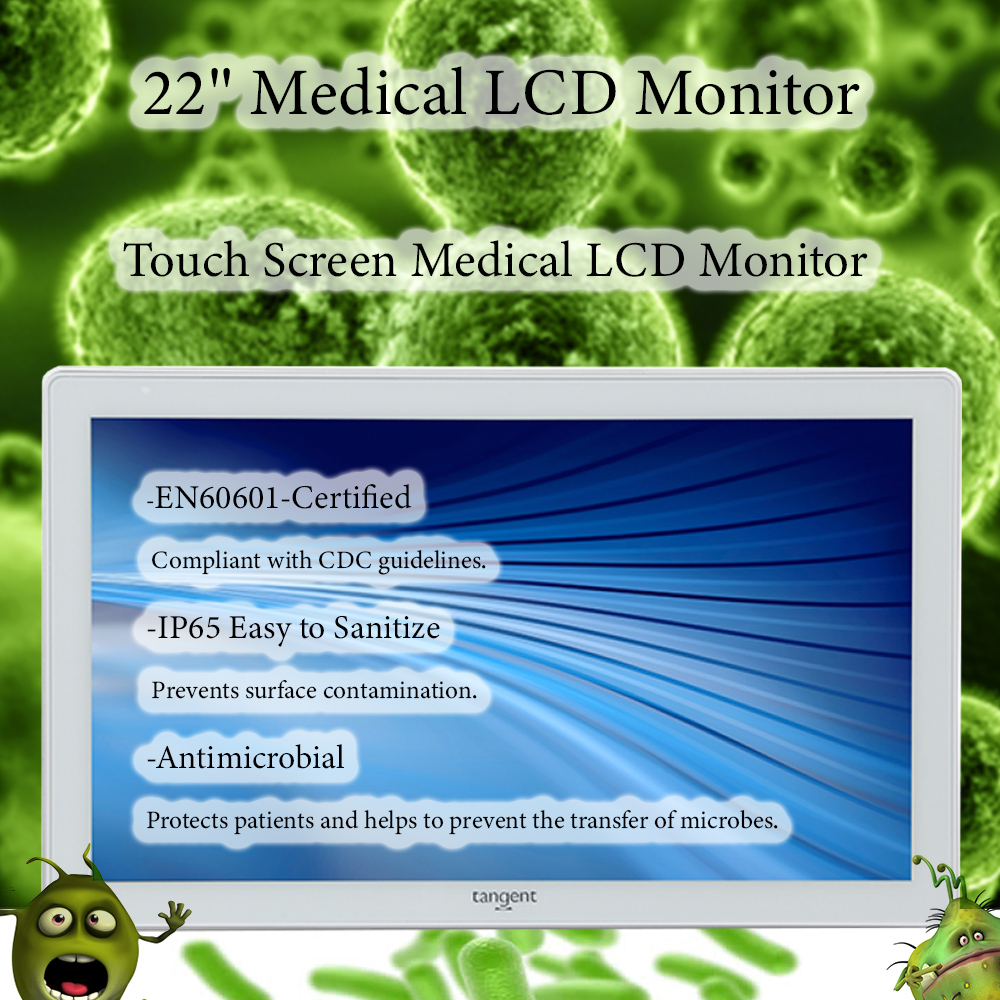

Another benefit of antimicrobial plastic is that the additives have been tested to last for the expected lifetime of the treated product, like Tangent’s Medical LCD monitors. Once infused into plastic, antimicrobial additives don’t leech from the surface, cause discoloration or affect the clarity of the plastic. This ensures that the equipment can be confidently kept in medical spaces to keep patients safe for years without degrading the quality of the device. Every Tangent Touch Screen Medical LCD monitor comes factory treated with an antimicrobial additive to battle surface contamination. The 22” Medical LCD monitor also has an IP65 rated front panel, which means it’s rated as dust tight and protected against water projected from a nozzle. One doesn’t expect a random hose to be shooting water around a hospital, but strange things are known to happen. Actually, this provides a very beneficial added layer of cleanliness to the LCD monitor. The monitor can be easily cleaned and wiped down with no chance of damaging it’s internal components or adversely affecting its touch screen capabilities.

Microbes and bacteria are a threat that is naked to the eye, and yet another invisible and potentially hazardous peril can arise from electronics in a medical setting. Before 1977, there was no standard for safety on medical equipment and electric shocks and shorts were commonplace. Since then the EN 60601-1 family of standards was developed. Its scope covers the safety, essential performance and electromagnetic compatibility of medical electrical equipment and related systems. Tangent’s Touch Screen Medical LCD is certified EN 60601 and is compliant with CDC guidelines. Painstaking measures are taken to ensure that these LCD monitors are safe, sanitary, and effective in a medical space. It’s VESA 75 mounting capability allows for affixing the LCD monitor to an arm, point-of-care cart, or stand.

Pair this sleek LCD monitor with one of Tangent’s antimicrobial, waterproof keyboards, and a rugged, fanless PC to truly experience a long-lasting, dependable, hygienic computer system. There is enough to worry about in a hospital settings without having to consider whether your computer components are making patients unwell or spreading dust and spores.