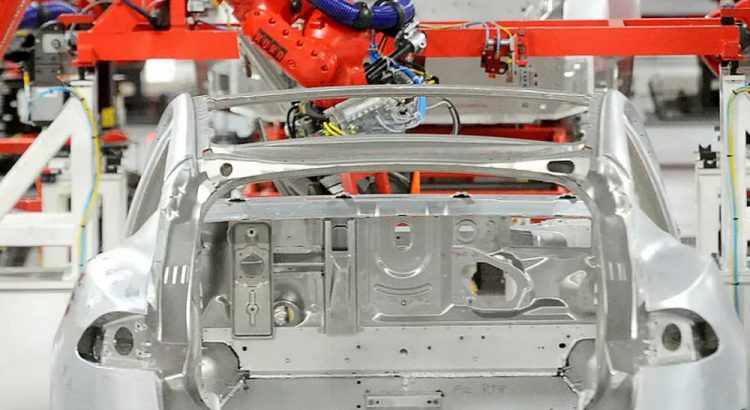

The automobile industry famously pioneered the assembly line, and since then has constantly innovated the manufacturing process of automobiles. In the information age, this innovation can be seen in the increasingly-computerized factory floor’s ability to produce cars with maximum efficiency. However, outdated or mismatched industrial computers can have the reverse effect on a factory, slowing […]