When we discuss the prevention of nosocomial infections in the hospital—clostridium difficile (C. diff), Methicillin-resistant Staphylococcus aureu (MRSA), Escherichia coli (E. Coli)— it is important to note all the various ways these diseases are transmitted. From one medical exam room to the next, medical staff carry such diseases across the hospital. It’s already well known […]

Month: January 2020

Fanless Industrial PCs For Every Sector

Industrial PCs have come a long way since their original implementation, and the rise of the internet has made these Industrial PCs both invaluable and necessary tools for every industrial sector. In a time where productivity is falling in the factory setting, the concerted use of industrial PCs to create smart factories is proving to […]

How Much RAM Do I Need in My Industrial PC?

When shopping for new industrial PCs, there are many important factors to consider. CPU age and clock speed, hard drive space, and availability of I/O ports are all crucial considerations to make when deciding on the equipment that will keep your facility running in the years to come. But one critical, and usually overlooked, aspect […]

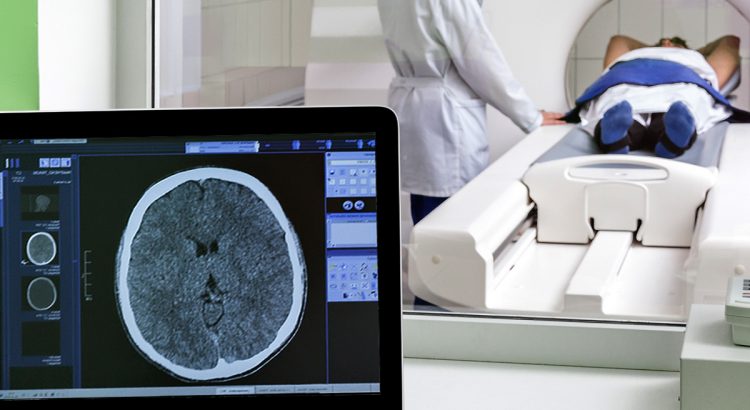

How Touchscreen Computers Can Aid Early Detection Efforts

Cardiovascular disease (CVD) and cancer are two of the leading causes of death globally, and the combat of these conditions is critical to improving general public health. The best methods of treating such diseases rely on the early detection of these medical issues, which is not always possible. Early detection efforts can be stalled by […]