Automobile Manufacturing Automation

The use of advanced technology in automotive manufacturing has been commonplace since the 1960s when car manufacturers first pioneered the use of industrial robots and then went on to make them standard in car assembly by the 1980s. Having seen tons of videos of robots welding chassis and components together on the automotive shop floor makes one think that the entire process is automated. But what’s surprising is that on the assembly side of things, automotive manufacturing is still quite people-intensive. In the past, industrial touchscreen computers were largely used for monitoring and quality assurance purposes. However, newer tech has seen the advent of things like collaborative robots that can help factory workers with challenging tasks, delivering materials, or assisting with heavy materials. Drones have been developed and deployed to inspect parts or potentially hazardous environments, while the factory staff control and investigate the proceedings on an industrial touchscreen PC. GM is even now using exoskeletons for repetitive operations in manufacturing. Workers wear a glove and they are given added strength and dexterity, but eventually they will also pass on their repetitive work tasks to a computer. Car manufacturers state that this is only the beginning in their quest for automation. In GM’s vision, the entire assembly floor will one day be a streamlined and automated flow of events.

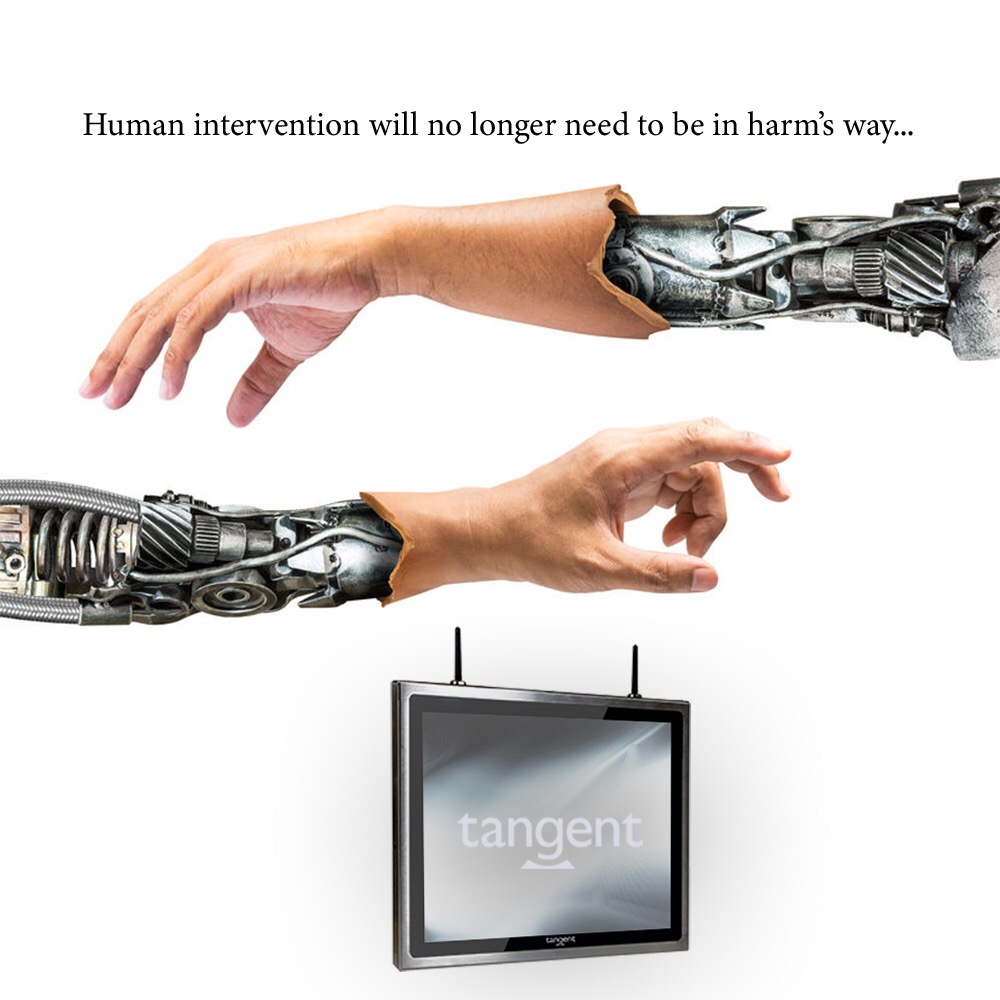

The place for human intervention will no longer need to be in harm’s way on a hazardous assembly line, but with the tools and technology to be able to complete the same tasks using industrial touchscreen computers. Tangent’s All-in-One industrial PCs are created to be ready for the great ideas and automations of the future, whilst being able to withstand and succeed in the harsh and demanding environments of existing manufacturing sites. The S Series industrial all-in-one comes in a 15 inch, 19 inch, or 22 inch touchscreen monitor, built with a stainless steel enclosure that is IP69K rated as being fully waterproof. This series is also offered with a fanless design for reliability, longevity, and a noise-free operation which can be critical in manufacturing plants that must minimize dust circulation or ambient sound. The CPU is an Intel 3rd Gen Core i5, offering best-in-class integrated media and graphic performance to keep up with ever evolving (and moving) assembly line requirements. The units are available not only with VESA 100×100 compliant mounting, but also an optional tilting side mount, or with a sunlight readable panel with UV protection coating. This industrial touchscreen computer doesn’t even need to be indoors to provide effective utility! Another convenience is the S-Series’ optional Intel wireless and Bluetooth connectivity, removing the need to route ethernet cabling to the computer. This prevents clutter and maintains a clean work environment.

The automotive industry is always looking for process improvement through the use of innovative, reliable technology. Supporting smarter and safer technological endeavors is the heart of Tangent’s industrial computer offerings. The S-Series industrial touchscreen PCs are but a shining sample of the targeted work that Tangent does to bring quality and scalability to the manufacturing floor.